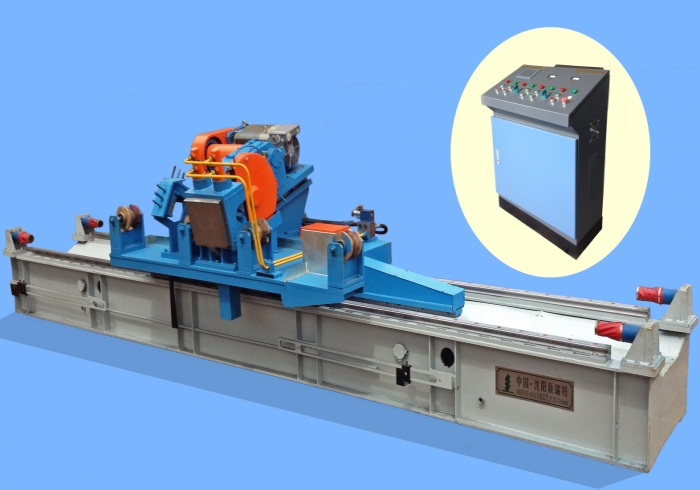

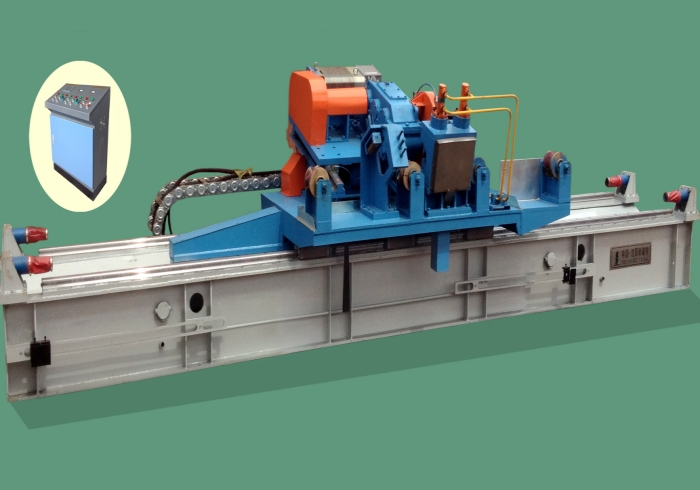

Cold Saw Flying Cut Off

Cutting tube or pipe is full of challenges. One of it is a clean cut that doesn’t need deburring. When chamfering is required, the chamfering tool lasts longer when used on a burr-free edge. Advance in blade geometry and coating technology had made tungsten carbide-tipped (TCT) or HSS circular saws a value option to solve this challenge.

Cold saw cut off machine sophisticatedly designed by SRET Equipment, runs safer, cut cleaner, and less prone to breakage. The cold saw can be operated either by HSS or TCT blades. The traveling carriage is accelerated by a reliable rack and pinion system, AC or DC driven. It run quietly .One of the most advantage of SRET Equipment cold saw flying cut off machine is accuracy. To get this best result, the machine is designed and programmed for precise feed and cutting speed control. An optimal cut depends on a precise speed control system. The ability to manipulate the blade speed and feed rate is critical to both mill line speed and blade life.

SRET Equipment has developed the software that performs the necessary calculations to determine the cutting paths, maximizing the cutting rate, and preventing collisions. It also provides the feeding system an accurate and backlash-free movement.

At SRET Equipment, cold saw cut off machine is designed to make a clean and very precise in-line cut without influencing the effective production speed on the basis of which the cut-off performance parameters are optimized. SRET Equipment has been recognized as the earliest pioneer and the foremost manufacturer in China for making cold saw flying cut-off machines

Value Highlights

- Centralized lubrication system for a better machine maintenance and longer service life

- Burr-free cutting without need for end facing process

- Various length of cutting without stopping the tube mill

- Easy-to-use computer based graphic interface

- Able to handle products of various shape: round, square, rectangular, open profile

- High cutting accuracy

- Remote monitoring function enabling the on-site operation status being assessed at remote locations

- Once programmed, no need for constant operator presence at control desk

Technical Data Sheet

| Model No. | Size (mm) | Thickness (mm) | Length (m) | Tolerance (mm) | Speed (m/min) |

| LFJ32 | Ø 12 – 32

□ 10 – 25 |

0.6 – 1.5 | 4.0 – 8.0 | ≤ ±1 | Max. 120 |

| LFJ60 | Ø 20 – 60

□ 15 – 47 |

1.0 – 3.5 | 4.0 – 12.0 | ≤ ±1 | Max. 105 |

| LFJ76 | Ø 32 – 76

□ 25 – 60 |

1.5 – 3.75 | 4.0 – 12.0 | ≤ ±1 | Max. 95 |

| LFJ89 | Ø 38 – 89

□ 30 – 70 |

1.5 – 4.0 | 4.0 – 12.0 |

≤ ±2 |

Max. 90 |

| LFJ114 | Ø 50 – 114

□ 40 – 90 |

1.5 – 5.0 | 4.0 – 12.0 |

≤ ±2 |

Max. 80 |

| LFJ127 | Ø 60 – 127

□ 40 – 100 |

2.0 – 6.0 | 4.0 – 12.0 |

≤ ±2 |

Max. 55 |

| LFJ165 | Ø 89 – 165

□ 70 – 130 |

2.0 – 7.0 | 4.0 – 12.0 |

≤ ±2 |

Max. 50 |